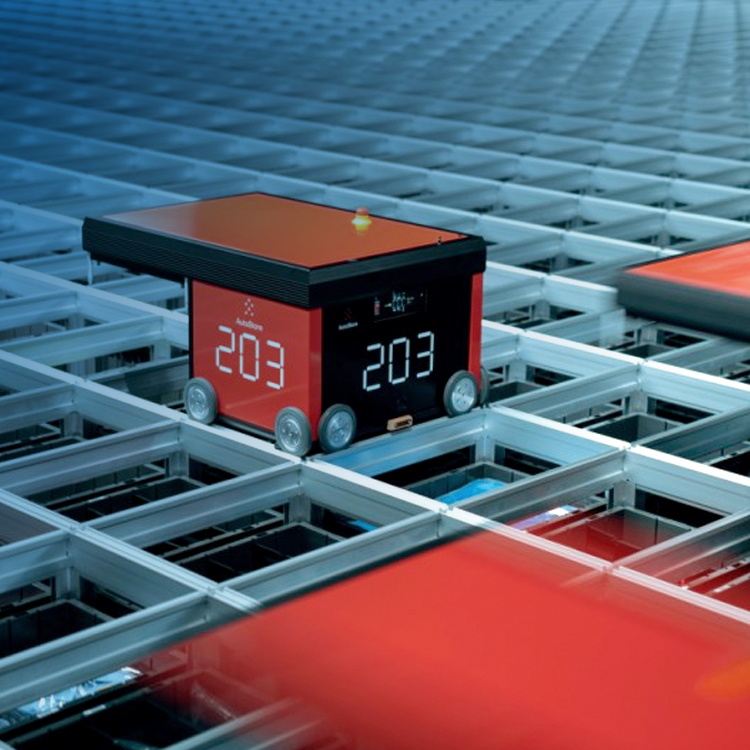

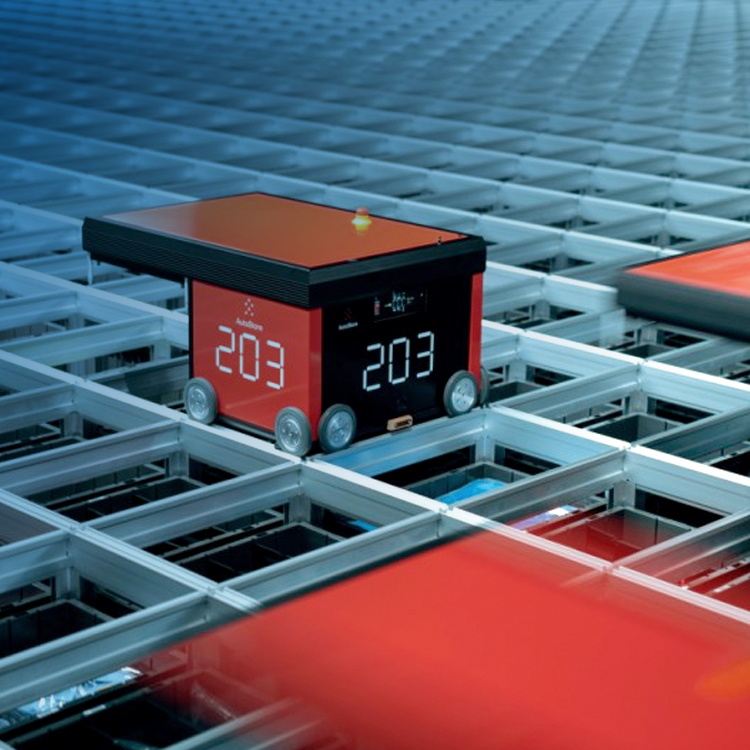

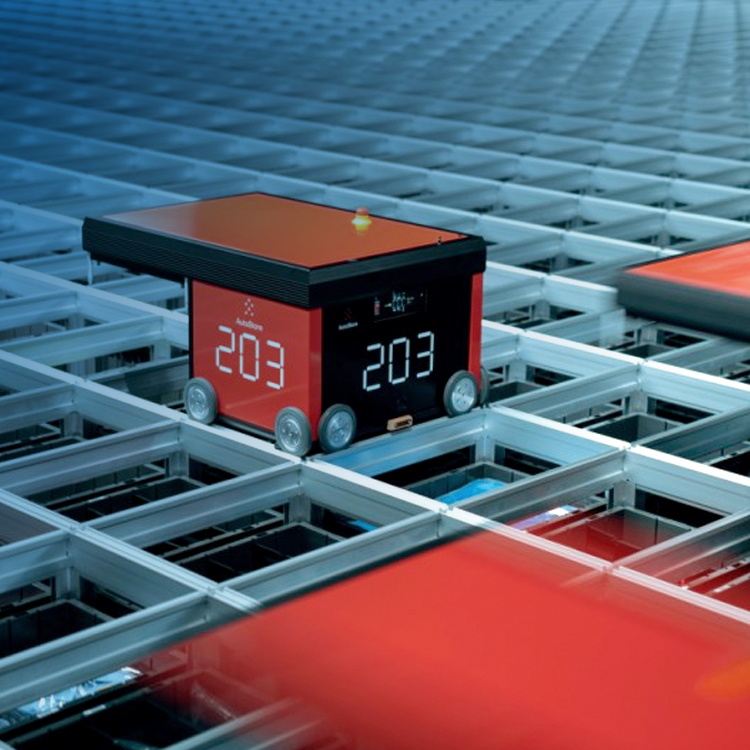

With this automation solution, we are ideally placed for the future – especially for e-commerce customers because the system, which resembles a tank tower, stores ranges of small parts in a very small space. Robots travel around the surface of the system automatically and access the goods on receipt of the order. They then bring the products to the order picking stations. This is where our employees take over: they take the articles out of the containers and pack them. Meanwhile, all order-relevant data flows automatically into our warehouse management system. This enables us to provide our customers with information about the current status of an order at any time. Another plus point: we can also scale the capacities of the AutoStore system at any time while the system is running. »This means we are well prepared for future growth,« says Rico von Hollen, assistant to the commercial management of L.I.T. Lager & Logistik GmbH. The other two sections of the warehouse are already equipped with high-bay racking with 25,000 pallet spaces and block storage areas. »By combining the various types of warehouse, we can react quickly and flexibly to individual customer requirements,« says von Hollen explaining the reasons for equipping of our new logistics centre. In addition to our e-commerce customers, we are currently also actively engaged there for the consumer goods and entertainment sectors. »But ultimately, the warehouse can be used for any industry,« says von Hollen, assistant to the commercial management of L.I.T. Lager & Logistik GmbH.

However, in our new building we are not limited in our service portfolio to storage alone. Comprehensive value-added services such as picking, packaging, display construction, quality control and product finishing are also part of our repertoire at the logistics centre.

For example, we have built a second floor especially for retail display fixtures so that there is sufficient space for their construction without impairing normal warehouse operations. The processing of returns management is also possible in the special areas; however, for this we need qualified personnel. So we are all the more pleased to welcome 40 new employees to our new logistics centre – from both the commercial and industrial sectors. They ensure that each of our customers not only receives exactly the services they need, but also the corresponding quality.

We also achieve flexibility in the LLC IV by equipping each of the three areas with their own loading and unloading docks. This enables us to deliver or collect the goods in any section of the hall. This also eliminates long and cumbersome transport routes from the warehouse to the loading bay.

Another major advantage of our new logistics centre is its location in the Bremen Cargo Distribution Centre (GVZ). According to the German GVZ Company, this is still the most popular site of its kind in Germany and occupies the second place throughout Europe. It is not only impressively located in terms of road links, but is also located in the immediate vicinity of seaports within the North Range. »Due to its excellent connections, the logistics centre is also excellently suited for intermodal transport,« says von Hollen. »In cooperation with our Air & Sea division , we can offer our customers variable transport options.« Including the new building, we now have four logistics centres in the Bremen Cargo Distribution Centre and another warehouse building in the Bremen industrial area. This gives us a total of more than 120,000 sqm of storage space.

With this automation solution, we are ideally placed for the future – especially for e-commerce customers because the system, which resembles a tank tower, stores ranges of small parts in a very small space. Robots travel around the surface of the system automatically and access the goods on receipt of the order. They then bring the products to the order picking stations. This is where our employees take over: they take the articles out of the containers and pack them. Meanwhile, all order-relevant data flows automatically into our warehouse management system. This enables us to provide our customers with information about the current status of an order at any time. Another plus point: we can also scale the capacities of the AutoStore system at any time while the system is running. »This means we are well prepared for future growth,« says Rico von Hollen, assistant to the commercial management of L.I.T. Lager & Logistik GmbH. The other two sections of the warehouse are already equipped with high-bay racking with 25,000 pallet spaces and block storage areas. »By combining the various types of warehouse, we can react quickly and flexibly to individual customer requirements,« says von Hollen explaining the reasons for equipping of our new logistics centre. In addition to our e-commerce customers, we are currently also actively engaged there for the consumer goods and entertainment sectors. »But ultimately, the warehouse can be used for any industry,« says von Hollen, assistant to the commercial management of L.I.T. Lager & Logistik GmbH.

However, in our new building we are not limited in our service portfolio to storage alone. Comprehensive value-added services such as picking, packaging, display construction, quality control and product finishing are also part of our repertoire at the logistics centre.

The other two sections of the warehouse are already equipped with high-bay racking with 25,000 pallet spaces and block storage areas. »By combining the various types of warehouse, we can react quickly and flexibly to individual customer requirements,« says von Hollen explaining the reasons for equipping of our new logistics centre. In addition to our e-commerce customers, we are currently also actively engaged there for the consumer goods and entertainment sectors. »But ultimately, the warehouse can be used for any industry,« says von Hollen. However, in our new building we are not limited in our service portfolio to storage alone. Comprehensive value-added services such as picking, packaging, display construction, quality control and product finishing are also part of our repertoire at the logistics centre.

For example, we have built a second floor especially for retail display fixtures so that there is sufficient space for their construction without impairing normal warehouse operations. The processing of returns management is also possible in the special areas; however, for this we need qualified personnel.

So we are all the more pleased to welcome 40 new employees to our new logistics centre – from both the commercial and industrial sectors. They ensure that each of our customers not only receives exactly the services they need, but also the corresponding quality.

We also achieve flexibility in the LLC IV by equipping each of the three areas with their own loading and unloading docks. This enables us to deliver or collect the goods in any section of the hall. This also eliminates long and cumbersome transport routes from the warehouse to the loading bay.

Another major advantage of our new logistics centre is its location in the Bremen Cargo Distribution Centre (GVZ). According to the German GVZ Company, this is still the most popular site of its kind in Germany and occupies the second place throughout Europe. It is not only impressively located in terms of road links, but is also located in the immediate vicinity of seaports within the North Range. »Due to its excellent connections, the logistics centre is also excellently suited for intermodal transport,« says von Hollen. »In cooperation with our Air & Sea division , we can offer our customers variable transport options.« Including the new building, we now have four logistics centres in the Bremen Cargo Distribution Centre and another warehouse building in the Bremen industrial area. This gives us a total of more than 120,000 sqm of storage space.

© 2025 L.I.T. AG · Otto-Hahn-Straße 18 · 26919 Brake Data protection | Imprint | Gender regulation | Manage consent | Complaint form | AGB

© 2025 L.I.T. AG · Otto-Hahn-Straße 18 · 26919 Brake

Data protection | Imprint | Gender regulation | Manage consent | Complaint form | AGB

© 2025 L.I.T. AG

Otto-Hahn-Straße 18 · 26919 Brake

Data protection | Imprint

Gender regulation | Manage consent

Complaint form | AGB