There can be no better praise: our customer, GE Healthcare, has honoured the L.I.T. specialists for medical technology in Wülfrath for their great work. The responsibilities of our team to the provider of medical technology solutions and services go far beyond the transport and storage

of highly sensitive ultrasound equipment. With comprehensive services such as repairs, configuration of new equipment and the processing of old equipment for resale, it offers our customers individual services that extend beyond the traditional boundaries of the logistics business. And it is work that they have now been doing for 17 years.

The successful cooperation has now been crowned with the presentation of the GE Healthcare

Award. With this award, the medical technology specialist acknowledges our ‘outstanding support’ in dealing with special healthcare products. »The award is a great accolade and reflects the appreciation for our work,« says Caner Kafaoglu, Team Leader of our GE Healthcare unit. »We are particularly proud of this because our services not only include classic logistics tasks.« In order to meet the customer’s special requirements, a team of 16 technicians and warehouse staff work exclusively for GE Healthcare in Wülfrath.

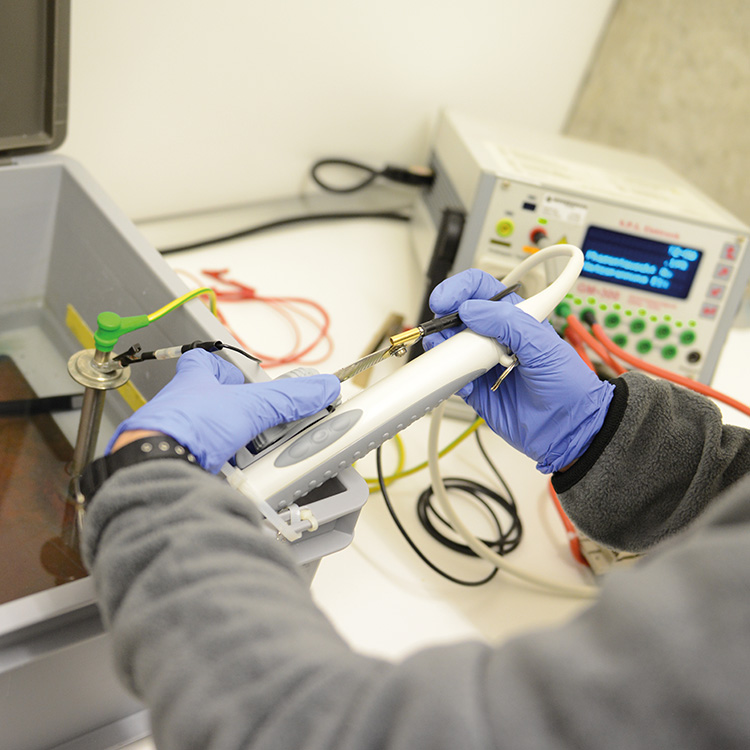

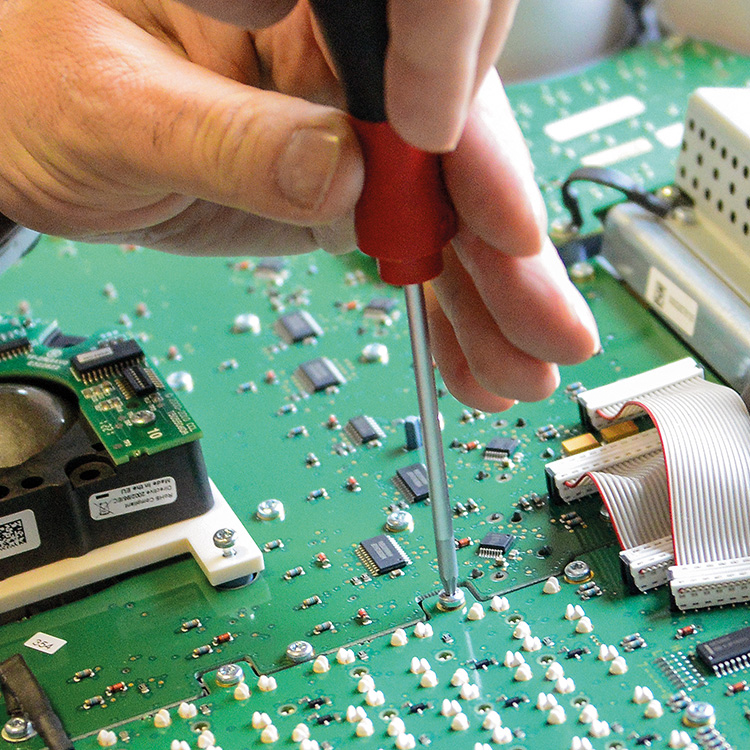

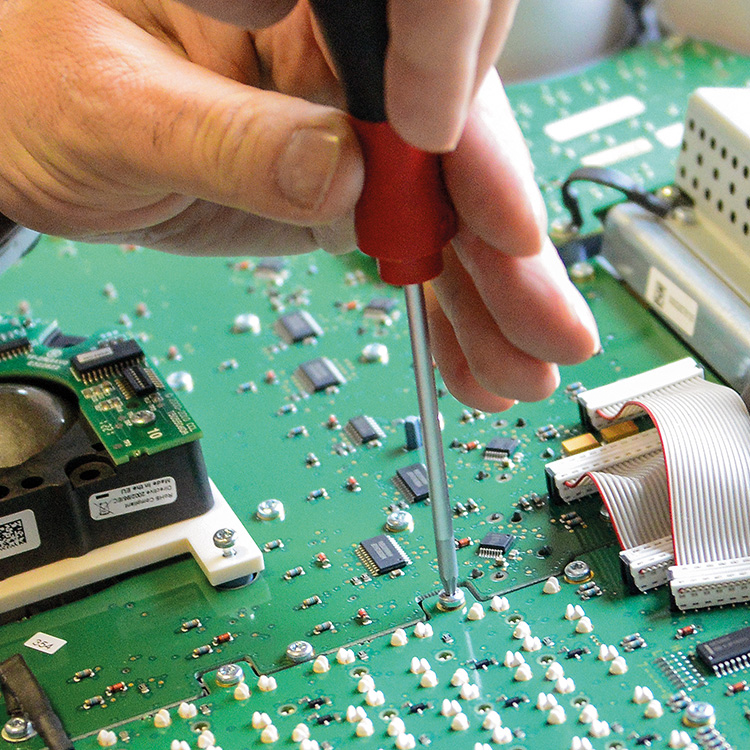

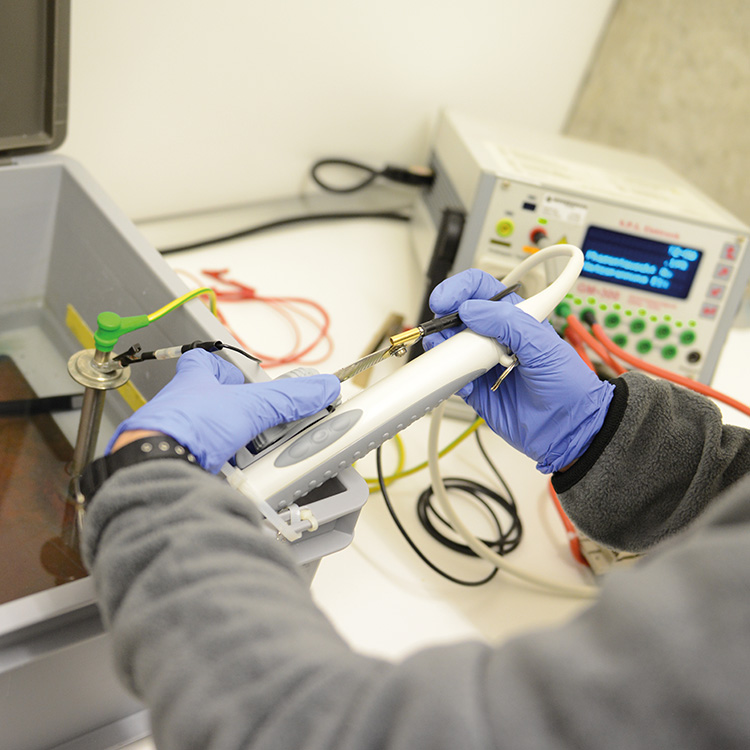

For example, our employees repair damaged ultrasonic equipment or prepare older systems for resale. This benefits medical practices and hospitals, where the devices can be quickly put back into operation. However, most of the work consists of configuring new devices and putting them through their paces. We equip the ultrasound devices with various functions, depending on the requirements of the GE Healthcare customer. These range from selecting the language to defining the type of probe that establishes contact between the signal processor unit and the patient undergoing investigation. The results of this work are individual, customer-specific ultrasonic devices.

Every year, the team in Wülfrath processes between 3,500 and 4,000 devices of various designs. This requires the exercise of extra caution when handling the highly sensitive ultrasound devices. In addition, seasonal fluctuations are a major challenge that our colleagues must repeatedly deal with. Bastian Kühl, branch manager in Wülfrath, knows that, things can sometimes get stressful: »The volume of orders is particularly high at the end of the quarter. Then it is a case of rolling up your sleeves and getting on with the work.«

But our service portfolio in Wülfrath is even more extensive. We have a total of 16,500 sqm of storage space there. Three out of six warehouses are specially designed for the storage of hazardous substances. The official approval in accordance with the Federal Immission Control Act allows us to store 8,744 tonnes of hazardous substances in these warehouses. A CO2 extinguishing system, a gas warning system as well as several ventilation systems and a special floor coating ensure the necessary safety. Around 6,600 pallet spaces in the high bay racking and block storage areas are available in Wülfrath, in which materials of various storage classes can be stored. These can be, for example, flammable, combustible or toxic substances. »This makes the location particularly attractive for customers from the chemical industry«, says Axel Schleef, managing director L.I.T. Health, Service & Logistics GmbH.

The successful cooperation has now been crowned with the presentation of the GE Healthcare

Award. With this award, the medical technology specialist acknowledges our ‘outstanding support’ in dealing with special healthcare products. »The award is a great accolade and reflects the appreciation for our work,« says Caner Kafaoglu, Team Leader of our GE Healthcare unit. »We are particularly proud of this because our services not only include classic logistics tasks.« In order to meet the customer’s special requirements, a team of 16 technicians and warehouse staff work exclusively for GE Healthcare in Wülfrath.

For example, our employees repair damaged ultrasonic equipment or prepare older systems for resale. This benefits medical practices and hospitals, where the devices can be quickly put back into operation. However, most of the work consists of configuring new devices and putting them through their paces. We equip the ultrasound devices with various functions, depending on the requirements of the GE Healthcare customer. These range from selecting the language to defining the type of probe that establishes contact between the signal processor unit and the patient undergoing investigation. The results of this work are individual, customer-specific ultrasonic devices.

Every year, the team in Wülfrath processes between 3,500 and 4,000 devices of various designs. This requires the exercise of extra caution when handling the highly sensitive ultrasound devices. In addition, seasonal fluctuations are a major challenge that our colleagues must repeatedly deal with. Bastian Kühl, branch manager in Wülfrath, knows that, things can sometimes get stressful: »The volume of orders is particularly high at the end of the quarter. Then it is a case of rolling up your sleeves and getting on with the work.«

But our service portfolio in Wülfrath is even more extensive. We have a total of 16,500 sqm of storage space there. Three out of six warehouses are specially designed for the storage of hazardous substances. The official approval in accordance with the Federal Immission Control Act allows us to store 8,744 tonnes of hazardous substances in these warehouses. A CO2 extinguishing system, a gas warning system as well as several ventilation systems and a special floor coating ensure the necessary safety. Around 6,600 pallet spaces in the high bay racking and block storage areas are available in Wülfrath, in which materials of various storage classes can be stored. These can be, for example, flammable, combustible or toxic substances. »This makes the location particularly attractive for customers from the chemical industry«, says Axel Schleef, managing director L.I.T. Health, Service & Logistics GmbH.

© 2025 L.I.T. AG · Otto-Hahn-Straße 18 · 26919 Brake Data protection | Imprint | Gender regulation | Manage consent | Complaint form | AGB

© 2025 L.I.T. AG · Otto-Hahn-Straße 18 · 26919 Brake

Data protection | Imprint | Gender regulation | Manage consent | Complaint form | AGB

© 2025 L.I.T. AG

Otto-Hahn-Straße 18 · 26919 Brake

Data protection | Imprint

Gender regulation | Manage consent

Complaint form | AGB